Lubricating method :

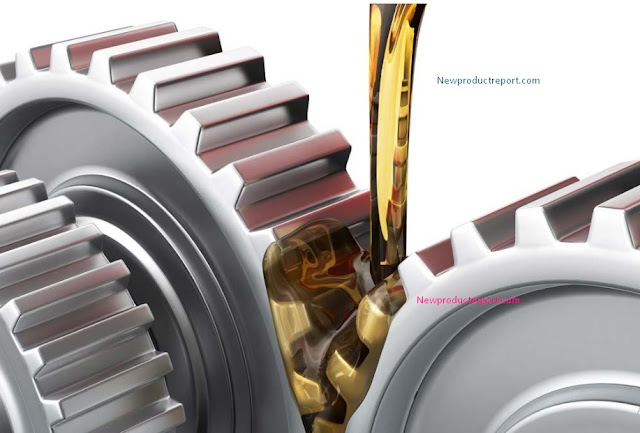

Lubricating oil lubricates all moving parts. Helps to rotate easily. It also lubricates the moving and rotating parts in the engine and prolongs the life of the engine. It is unthinkable to operate the engine without this method.

20 W denotes the lowest temperature by 50 = 20 (grade). W denotes the highest temperature by winter 50 (grade). The lower the grade of lube oil, the thinner the lube oil. For example, the grade of grease is 250 to 300.

|

| Lubricating method |

What is the purpose and function of lubricating oil?

1. Reduces the corrosion rate of the moving and rotating parts of the engine and reduces energy dissipation for easy operation.

2. Protects engine parts from rust.

3. Acts as a cooling agent to keep engine parts cool.

4. Acts as a cleaning agent and washes away dirt, carbon, corroded metal particles, etc. from engine parts.

5. The gap between the piston and the cylinder wall is sealed so that nothing from the combustion chamber leaks into the crankcase.

6. Increases the life of the engine by reducing noise by withstanding the impact between the engine parts and the bearing surface.

Amount of engine lube oil according to Sonalika tractor model:

|

S.N |

Model Name |

Luboil |

|

01 |

DI-730 |

6 Litters |

|

02 |

DI-745/45Rx |

8.200 Litters |

|

03 |

DI-750/50Rx |

8.200 Litters |

|

04 |

Supreme DI -35 |

8.200 Litters |

|

05 |

All Rounder

DI-55 |

8.200 Litters |

|

06 |

DI-55Rx |

8.200 Litters |

|

07 |

Tiger 60 Max |

11.300 Litters |

|

08 |

DI-60/60Rx |

11.300 Litters |

|

09 |

DI-75/ Tiger 75Max |

11.300 Litters |

|

10 |

DI-90 |

11.300 Litters |

Greasing Point:

The rules for greasing, especially the front wheel hub and rear wheel, should be done every two days and the rest should be greased once a week.

|

S.N |

Grease

Point Name |

Grease

Points Number |

|

01 |

Center

PIN |

01 |

|

02 |

Kingpin

right/left |

02 |

|

03 |

Front

Wheel Hub Right/Left |

02 |

|

04 |

Ty

Rod Ind |

02 |

|

05 |

Truck Rod Ind |

02 |

|

06 |

Clutch

Ecuiter Shaft Right/Left |

02 |

|

07 |

Clutch Pedal Shaft |

02 |

|

08 |

Brake

Pedal Shaft |

02 |

|

09 |

Back

wheel right/left |

03 |

|

10 |

Lifting

Rod and Leveling Rod |

04 |

|

|

DI-90 Total Grease Point |

22

points (farming tractor |

Faults and remedies of the lubricating method.

|

S.N |

Problems |

Because |

Remedy |

|

01. |

Engine oil leaks. |

|

|

|

02. |

Engine oil pressure shows low. |

|

|

|

03. |

Lube oil rises to the head of the

piston. |

|

|

There are 7 important aspects to check when setting up an engine.

1. You need to check the clearance of the thrust washer when setting the crankshaft.

2. The clearance of main and big-end bearings should be checked.

3. The pressure of the good pump needs to be checked.

4. Clearance of the piston, piston ring, the liner should be checked.

5. Engine timing needs to be checked.

6. Check if the engine valve is leaking. And the head bolts have to be tightened well.

7. Tapate clearance needs to be checked.