Fuel Method:

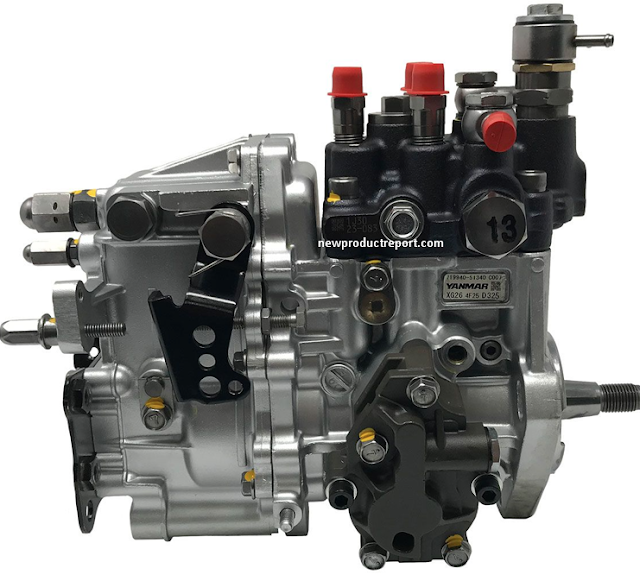

The fuel system works with the help of a high-pressure pump by spraying diesel in the compression chamber of the engine cylinder through the high-pressure injector in a timely manner resulting in firing in the cylinder.

Fuel pump runs but no pressure:

This is called the heart of the engine. Fuel pump work is given to the engine cylinder by high pressurizing the fuel. A pump has many components and the plaza is very dry.

Either way, if there is a leak or air somewhere in the fuel line mixed with the particulate water adulterated diesel kerosene in the pump, the plaza is destroyed very quickly.

This means that in order to keep the fuel pump in good condition, you have to use the original micro fuel filter and good diesel all the time. The opening pressure of the Sonalika tractor's fuel pump is 220 to 250 bar.

Injector:

Its job is to spray the high-pressure fuel obtained from the high-pressure pump in the compression chamber of the engine cylinder-like tiny particles of mist. The better the spray, the more power the car will have. Two types of injection are used in Sonalika tractors.

1. S-type 2. P-type. The S-type nozzle has four and the P-type nozzle has five. In other words, if the diesel is dirty, the holes will be closed in a short time. As a result, it will be difficult for the tractor to take the load and black smoke comes out through the silencer box.

What is meant by fuel pump timing?

At the right time i.e. compression stroke 10 to 30 degrees before reaching TDC. The system of fuel injection events is called injection timing or pump timing.

What is Fuel Pump's Timing Advance and Retard?

If the fuel injection is before the right time it is called advance and if it is after the right time it is called retard. If the fuel pump turns in the opposite direction, the timing will be returned.

What will be the problem if the fuel injection timing is not right?

1. Fuel cannot go completely, that is, maximum power cannot be obtained from fuel.

2. Fuel will be wasted.

3. The engine will overheat and the engine will not sound right.

4. If it is advanced, black smoke will come out and if it is returned, white smoke will come out.

There are 7 important aspects to check when setting up an engine.

1. You need to check the clearance of the thrust washer when setting the crankshaft.

2. The clearance of main and big-end bearings should be checked.

3. The pressure of the good pump needs to be checked.

4. Clearance of the piston, piston ring, the liner should be checked.

5. Engine timing needs to be checked.

6. Check if the engine valve stands leaking. And the head bolts have to be tightened well.

7. Tapate clearance needs to be checked.

Thanks for reading......